BORSIG ETHYLENE RECOVERY UNIT

Ethylene Recovery for Production of Polyethylene (PE) and Production of Ethylene Oxide (EO) and Vinyl Acetate Monomer (VAM)

The Application

During the production of polyethylene (PE) one typical process step is the degassing of PE powder and downstream pressure condensation to recover the hydrocarbons. The residual nitrogen purge gas stream is still rich on non-condensable hydrocarbons and monomer. To prevent enrichment of inert gas a side stream is typically sent to the flare and also affects a loss of monomer and hydrocarbons.

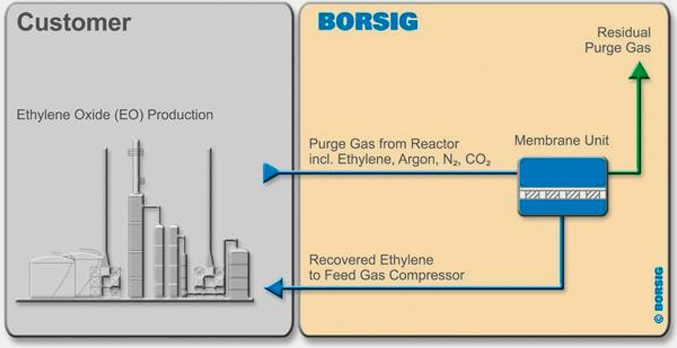

Similar purge gas streams can be identified in vinyl acetate monomer (VAM) and ethylene oxide (EO) processes. For example the inert gas Argon must be purged out of the process to prevent enrichment. Furthermore internal distillation overhead vents and other reactor purges can be treated.

All these procedure effect

• Substantial loss of ethylene monomer and of other solvents

• Increased flare gas streams and therefore secondary emissions to the atmosphere.

INFORMAÇÕES TÉCNICAS:

Our Solution

The BORSIG Ethylene Recovery Unit is an easy add-on system and can be considered in existing and new process installations. The purge gas stream, typically pressurized and containing the ethylene monomer and disturbing inert gas, is fed into the membrane system, while the permeate side of the membrane separation stage is fed back to the existing process gas compressor’s suction side. By means of the resulting pressure difference and the hydrocarbon selective membrane material, the purge gas stream is separated into the inert gas enriched off gas and the recycled ethylene-rich permeate stream. Typically no other equipment or machinery is required, which results in a very simple and reliable process solution.

The Benefits

• Easy installation in new plants and easy retrofit of existing systems

• Easiest solution – Key equipment membrane separator only, quick installation and easy implementation by skid-mounted modular design

• Very short payback period

• Low maintenance

• Safe and reliable operation

• Tailor-made design to meet customer’s codes and specifications